FAQ

Technology & competitive edge

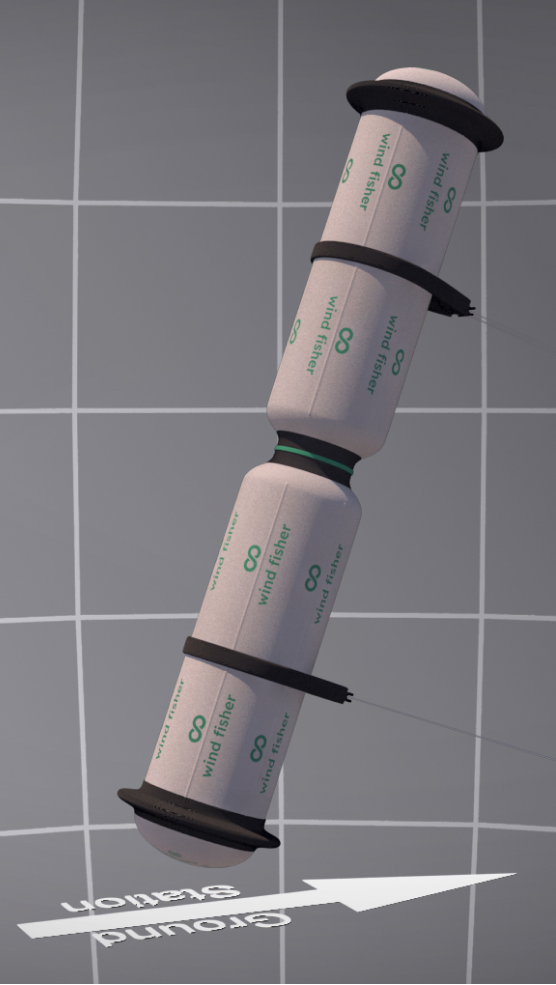

- The MAG100 is 25m long and 4 m in diameter.

- The MAG is filled with helium at a pressure slightly greater than atmospheric pressure: 30 millibars gauge.

- The MAG is lighter than air, because the buoyancy of the helium is slightly greater than the weight of MAG.

- Our cylindrical MAG is very safe by design in all flight conditions, compared to other airborne wind energy concepts. Being lighter than air, take off and landing is smooth and safe. The cylindrical design gives it significantly better gust and turbulence tolerance, compared to kites or rigid wings. In addition, our efficient structural shape leads to lower overall material costs for a given power.

- The aerodynamics of the MAG lead it to having a greatly reduced noise impact compared to traditional wind turbines. Regarding visual pollution, when there is no wind, the MAG is simply returned to the ground station and disappears from the landscape.

- Electricity is generated in the ground station: the MAG pulls on the cables, which unwind and drive a generator located in the ground station.

- To bring back the MAG during each cycle, you need to spend around 15% of the average energy produced in that cycle.

- The MAG uses a natural buoyancy to lift away from the ground station. The piloting of the take-off phase is safe and fully automated.

- To land, the MAG’s rotation is greatly reduced and the pulling force on the cables returns it to the ground station.

- The MAG flies at heights between 200 and 300 m. The flight does not use much space! The MAG flies inside a plane surface. About 500m span. Unlike a kite, the MAG does not go up and down in the air. Just from left to right and back.

- If there is a hurricane alert, we simply lower the MAG and secure it to the ground station. We can even depressurize the inflated airbeams to reduce the surface area exposed to wind. This makes the MAG useable in hurricane-risk zone, unlike traditional wind turbines

- Please visit Airborne Wind Europe, our industry association, for details on how airborne wind energy compares to traditional wind turbines : https://airbornewindeurope.org/benefits/

Regulation & market

- Wind Fisher’s MAG is regulated as a tethered gas balloon and can be flown anywhere except in close proximity to airports or over urban areas. Initial installation will fly over unpopulated agricultural fields and eventually the MAG will overfly rural to sparsely populated suburban areas.

- Our preliminary analysis shows that we reduce the carbon footprint of wind energy by half compared to a traditional wind turbine, reducing from 14g CO2e per kWh for a traditional wind turbine to 7g CO2e for a MAG.

- Yes, a MAG can be installed offshore. The preferred option is a floating foundation which is much smaller than what a traditional wind turbine of equivalent power would require due to the lack of overturning moment associated with a large tower.

- It takes only two days to install and test a MAG, assuming the electrical connection has been made available in advance

- Replacing diesel fuel with renewable energy is a 40B€ market opportunity. A MAG produces renewable electricity locally thus reducing the amount of fuel burn. However, a diesel generator is still required for when the wind doesn’t blow. Another advantage is that Wind Fisher’s ground station can use its flywheel energy storage system to reduce the size and optimize the efficiency of a diesel genset by providing a short duration frequency response reserve.

- Decentralized renewable energy (DRE) is a 60B€ market opportunity for grid connected systems.

- A competitive levelized cost of energy is below 180€/MWh for micro-grid applications and below 100€/MWh for grid connected applications. We target the first market from the start with our first MAGs, produced by external suppliers. We target the second market after two years, when we produce the MAGs internally, and costs have been improved.